COAL SHIPPING TERMINAL

Problem

This large coal export terminal in South America sits in the middle of a tourist region of the country. Environmental complaints have been filed against the company to improve dust suppression at the various material handling areas throughout the plant.

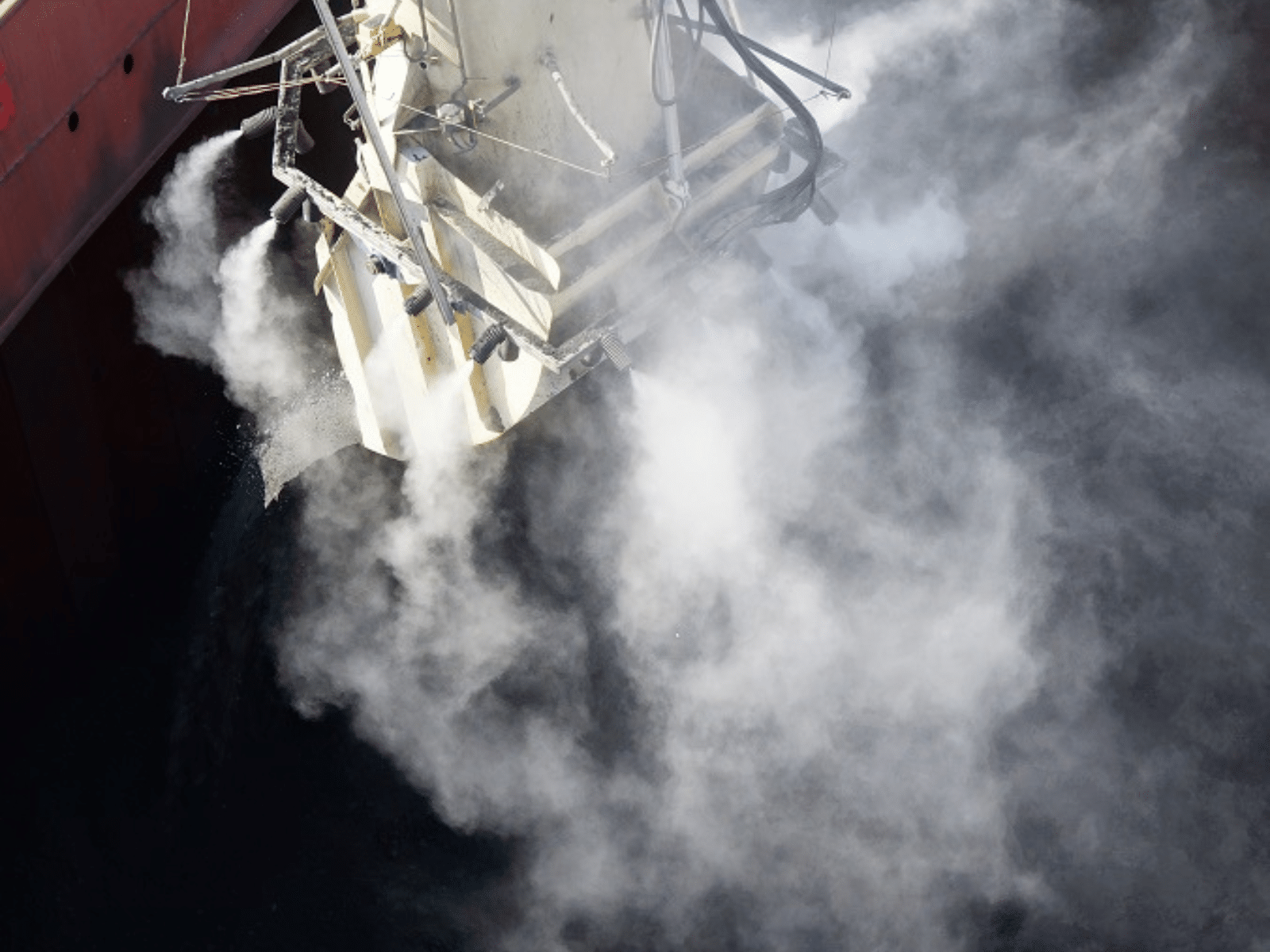

The client first looked at all areas that were using water sprays and found they were ineffective in providing efficient suppression. Further, by adding moisture to the product they were being charged additional cost for the shipping of the added moisture weight. These areas included the transfer points, bucket wheel reclaimers, railcar unloaders and shiploaders.

Solution

DSI put together a plan in stages attacking each area step by step. In many cases, the existing water lines were used to feed the Dry Fog systems, which were more efficient in suppression and added less than 0.05% moisture by volume. This not only was able to reduce the dust complaints from neighboring facilities and hotels, but also reduce the weight of outgoing coal, therefore paying back the cost of the systems.