Wind Fence DustTamer™ Systems

Wind erosion causes an estimated 30% of storage pile dust emissions. Reducing wind speed equates to less dust.

DustTamer™ reduces dust emissions caused from wind erosion on open stockpiles. Our wind fence material is designed to exert a drag force on oncoming wind and reduce wind speeds up to 75% within the sheltered area. Our systems prevent dust that is generated by oncoming winds, material loading and unloading, and equipment and vehicle movement from becoming airborne.

DUSTTAMER™ Wind Fence Theory

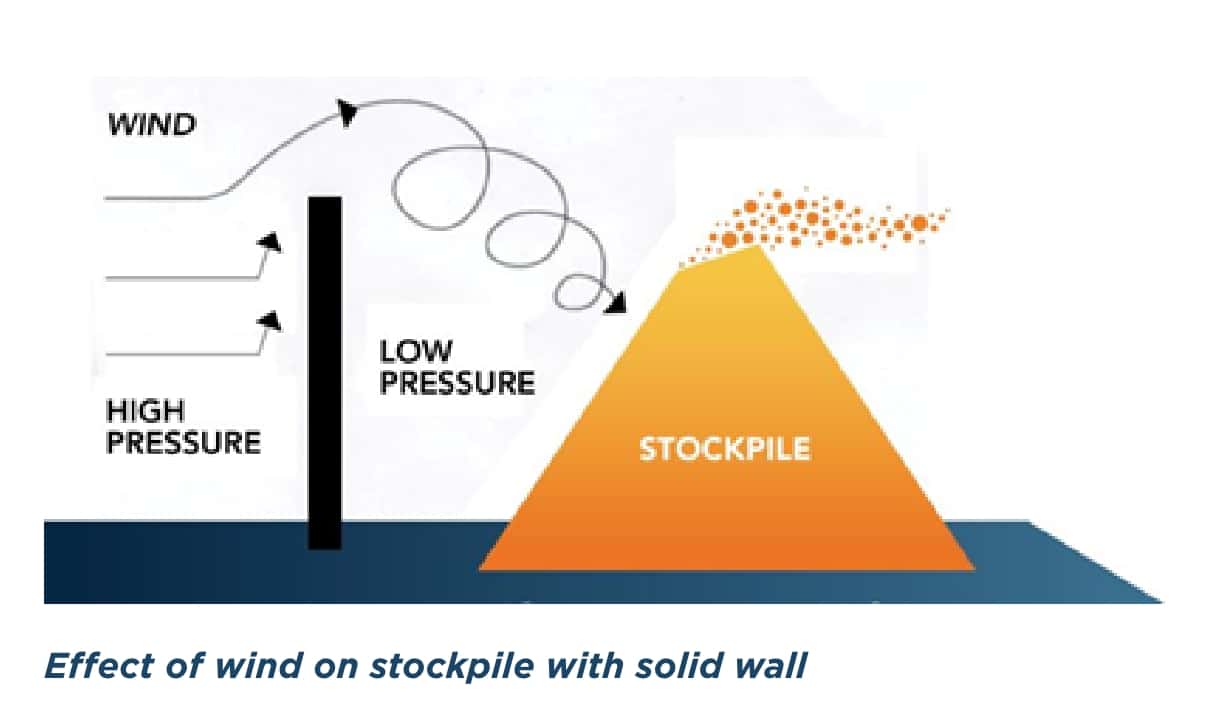

The concept behind how a wind fence works is easy to understand. If a solid wall is used as a wind break, two different pressure zones are created as wind movement towards the wall increases. Because impermeable materials, such as a solid wall only deflect wind, not reduce it, any openings for equipment access or areas on either side of the wall can funnel high pressure ambient air into the low pressure interior. This results in increased air velocities within the protected area. This will also cause wind to flow over the wall and create a turbulent movement on the other side, amplifying the wind speed and creating more particle uptake.

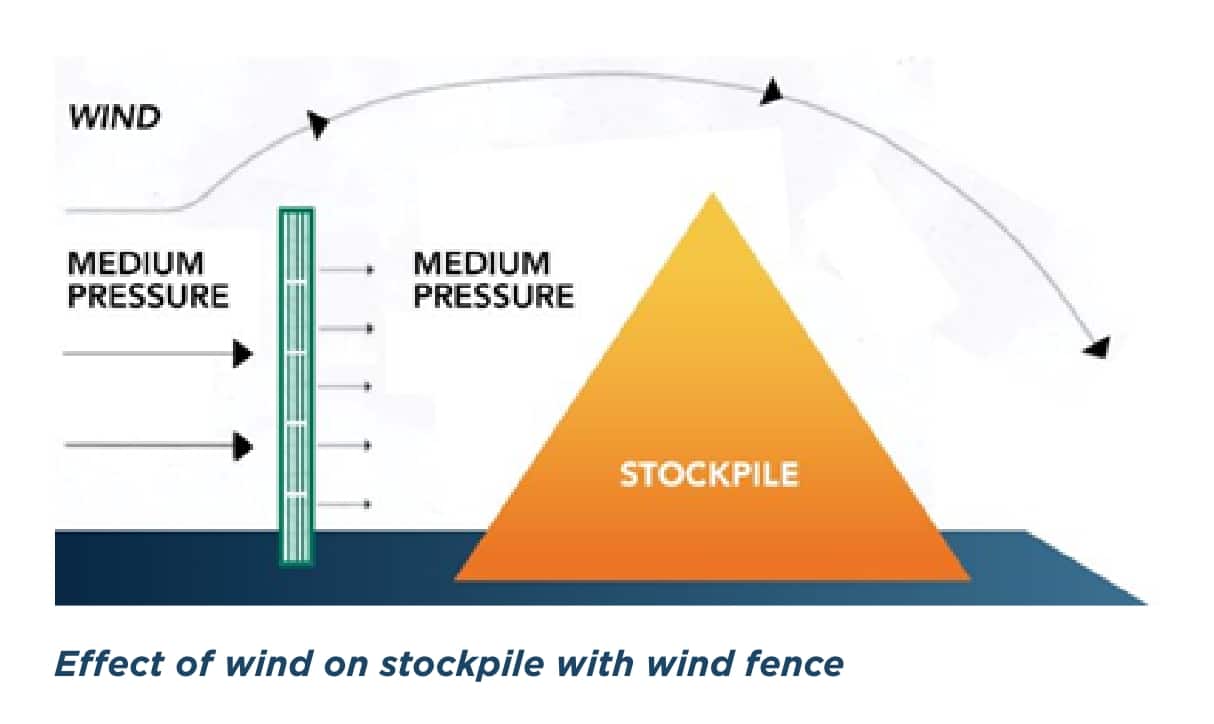

Conversely, if a porous material is used, high velocity wind that moves toward the stockpile will be diminished as the porosity will allow for air to pass through and equalize differential pressure on either side of the barrier.

Wind Velocity Reduction

The primary purpose of a wind fence is to reduce wind velocity moving towards the storage pile and prevent particle uptake in the protection zone. Particle movement can take place in three different ways: rolling, saltation, or suspension.

- Rolling / Creep: Rolling and sliding movement of larger particles along the ground. Depending on wind velocity, material can be moved to another pile.

- Saltation: Movement of particles by a series of short bounces along the ground which also dislodges additional particles with each impact.

- Suspension: Fine particles move parallel to the surface and upward into the atmosphere by strong winds. Particles can be carried high into the atmosphere, only returning to earth when wind subsides or they are carried down with precipitation. Suspended particles can potentially travel hundreds of miles.

DustTamer™ wind fence material is designed to exert a drag force on oncoming wind and reduce wind speeds up to 75% within the sheltered area.

By controlling wind speeds, it is possible to control levels of particulate matter in the air. The material allows a portion of the wind volume to penetrate through the screen as well as deflect the remainder of the wind to the surrounding sheltered area. Subsequently, the velocity lowers to the point required to initiate particle movement and prevent suspension. Air passing through the screen is referred to as “displacement flow”. The displacement flow and wind velocity are determined by the permeability of the screen.

DUSTTAMER™ Products

Dust Solutions has the capability of handling all aspects of your wind fence project from design to structural engineering, material supply and complete installation.

Total Wind Reduction Systems

Dust Solutions supplies all components for your DustTamer™ Wind Fence System:

- DustTamer™ Fabric is knitted from industrial grade woven polyester, resistant to UV rays, in-climate weather and temperature extremes. Its unique ability to be stretched and tensioned to over 500lbs. of pull prevents “flagging” of the material and consequential damage due to abrasion. The slotted design prevents dust from plugging the fabric like basket weave material will do.

- Attachment hardware is comprised of specially designed galvanized stand-off metal brackets, lockbars and attachment screws to attach DustTamer™ material to support your columns. Attachment hardware enables tensioning and installation without the need for pre-drilling.

- Tie Wraps made of UV resistant nylon are the most common ties that we supply for tying runs of fabric together. This prevents the screen material from rubbing on an adjacent fabric run.

CFD Modeling for Wind Fence Design and Placement

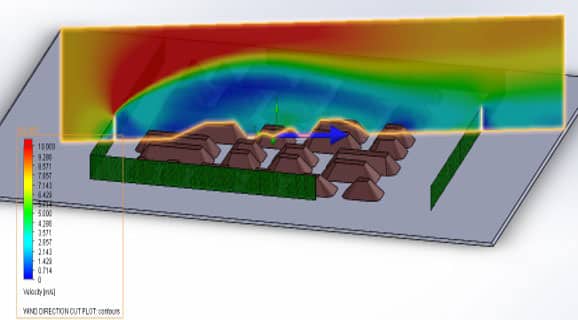

Dust Solutions, Inc. uses computational fluid dynamic (CFD) modeling to conduct in-depth engineering analysis of complex air and dust flow patterns that may be encountered at a project site. By analyzing conditions such as wind velocity, pressure, temperatures, topography and presence of existing structures, we accurately determine the location, fence structure height, and material porosity required to effectually reduce wind speeds and resulting particle uptake in a given area. Using hard data, we design and plan for the most effective dust suppression and mitigation solution possible.

Turn Key Installations

Dust Solutions has the capability of handling all aspects of your wind fence project from design to structural engineering, material supply and complete installation. All installations are warrantied and provide protection and containment within the specified project area. Our installation partners have installed millions of square feet of netting and wind fence material and have expertise in pole installation. We provided custom tailored solutions to each project application, providing the most effective wind break possible for your dust issue.

DUSTTAMER™ Comparisons

Other technologies can’t compete. DustTamer™ excels as the most effective, safe and economic method of dust suppression in heavy industrial app

DUSTTAMER™ Wind Fence vs Basket Weave Material

Basket weave material is standard netting for wind fences, shade cloth, and sport netting. The material is weaved together in a cross hatched pattern. Although openings in the material allow air pressure to equalize on both sides of the fence, basket weave and cross hatch stitching are known for their rigidity which also causes the fabric to be prone to clogging. Over time, material buildup and blockage with fuel materials can lead to the structure acting similarly to a solid wall configuration. Material blockage affects the effectivity of the fence and can also lead to material breakage with high wind loads. DustTamer™ fabric’s design does not experience buildup issues due to its flexible, slotted design which provides self-cleaning qualities.

CFD modeling comparison shows a non-clogged versus a clogged fence. The clogged fence creates an effect like a solid wall, which generates turbulence on the other side creating higher wind speeds impacting the stockyard or material piles.

DUSTTAMER™ vs Metal Wind Fences

Metal wind fences are typically manufactured from galvanized steel with holes punched in the metal to create a porous media. Similar to basket weave material, metal fences are even more rigid and therefore prone to clogging. Material easily sticks to openings which results in decreased effectivity of the structure as a windbreak.

Other limitations of metal wind fences include the potential to rust over time depending on the environment. Metal fences are also heavier in weight than fabric wind fences. The increased weight usually allows for a maximum span of 5-6m from post to post, resulting in additional infrastructure costs to erect the fence.

Although the material is galvanized, it still can rust over time with around an 8-10 year life. The beginning of rust can be seen on the infrastructure and fence after less than 5 years.